Vanadium is a hard, silvery grey, ductile and malleable speciality metal with a resistance to corrosion, good structural strength and stability against alkalis, acids and salt water. The elemental metal is rarely found in nature.

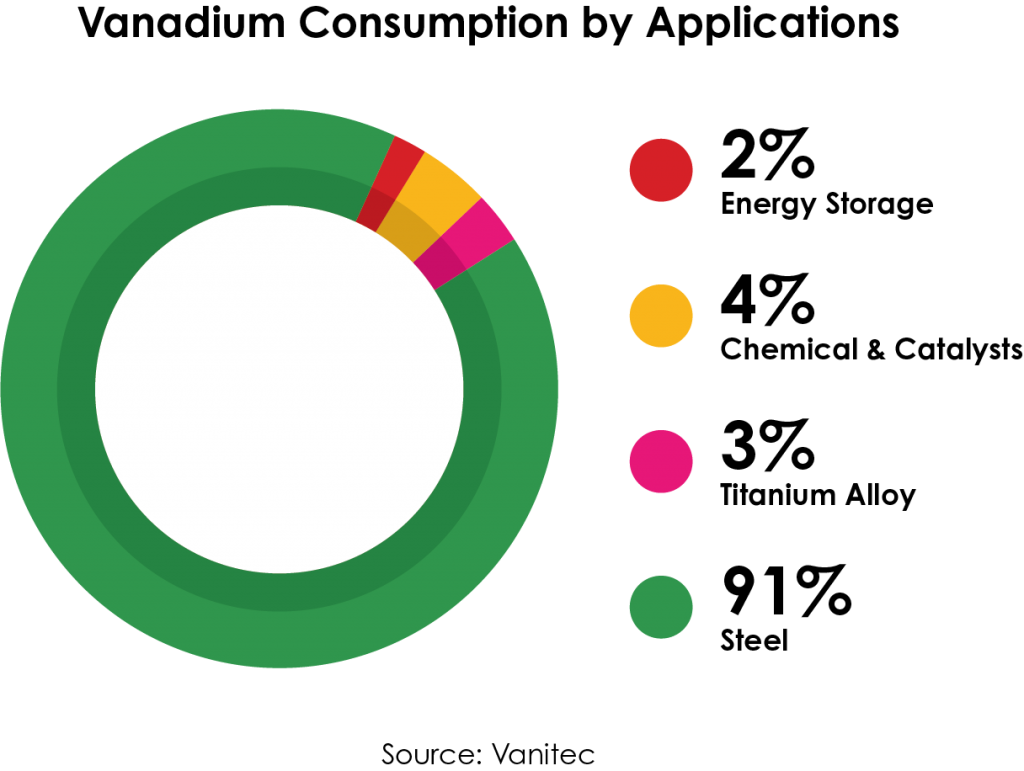

The main use of vanadium is in the steel industry where it is primarily used in metal alloys such as rebar and structural steel, and aircraft. The addition of a small amount of vanadium can increase steel strength by up to 100% and reduces weight by up to 30%.

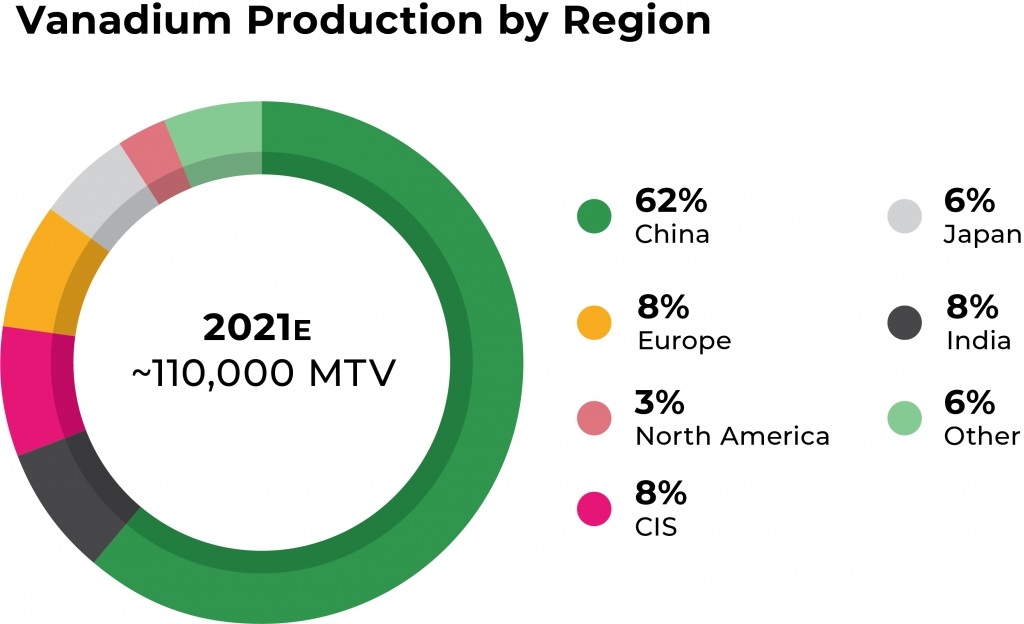

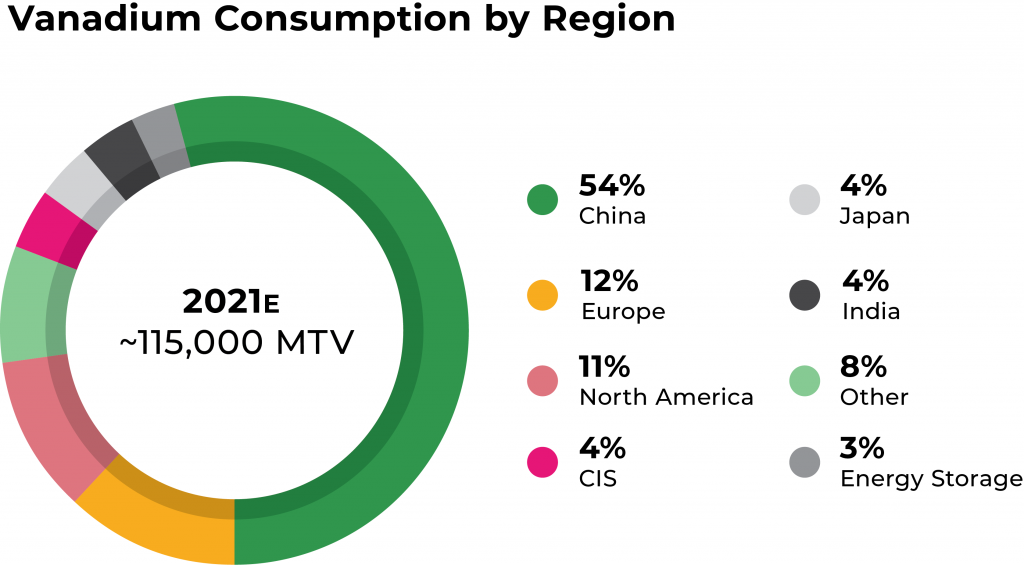

In addition, China recently revised steel product standards in an effort to combat recurring risk from structural damage caused by a series of earthquakes in 2008. China indicated a desire to improve the strength of reinforced steel bar or “rebar” in particular as rebar is a common framework within concrete structures. This has seen an increasing demand for vanadium as the intensity of use in steel rises.

Vanadium is increasingly being sought after for the growing stationary storage vanadium redox flow battery (VRFB) market. The demand from the VRFB market is expected to grow significantly as they become the battery of choice for large-scale renewable energy projects.

Growing Demand from Energy Storage

An emerging and likely very significant use for vanadium is the emerging long duration energy storage (battery) sector with the expanding use and increasing penetration of the vanadium redox flow batteries (VRFB).

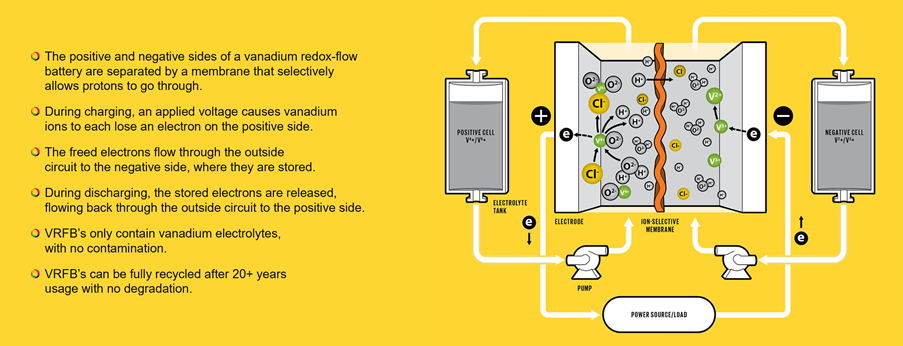

VRFBs are a rechargeable flow battery that uses vanadium in different oxidation states to store energy, using the unique ability of vanadium to exist in solution in four different oxidation states. VRFBs provide an efficient storage and re-supply solution for renewable energy – being able to time-shift large amounts of previously generated energy for later use – ideally suited to micro-grid to large-scale energy storage solutions (grid stabilisation).

Some of the unique advantages of VRFBs are:

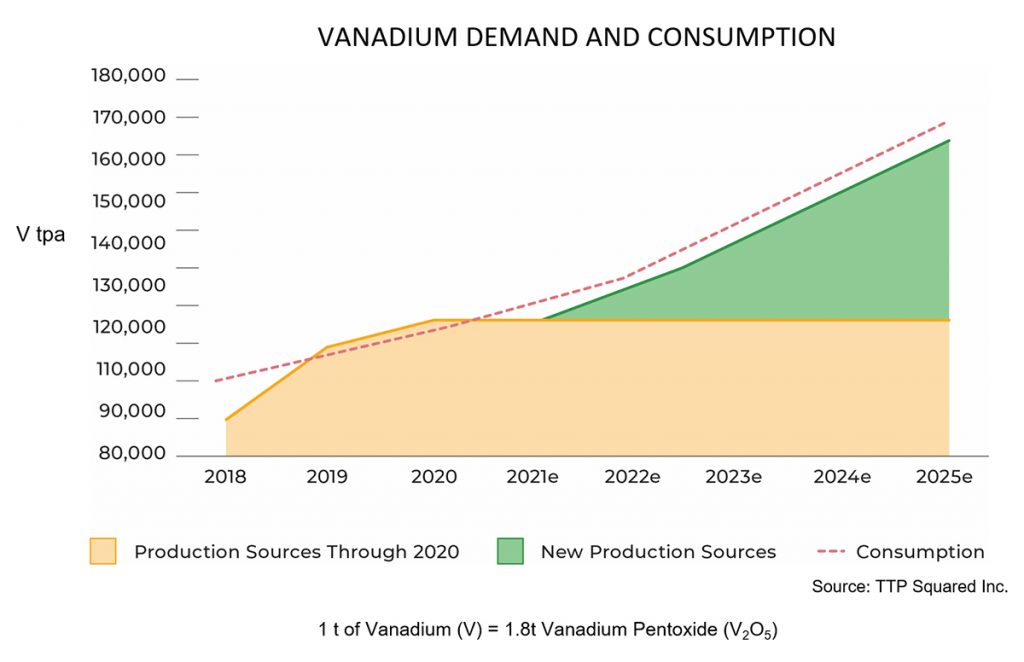

With demand continuing to grow, new primary mines like the MTMP will need to be developed to fill the supply gap.

Vanadium consumption in VRFB is forecast to grow to ~25,000t V by 2025. TMT’s forecast production is ~7,000t V per year.